As something that can have adverse impacts on the environment if not managed or properly controlled, mine materials must be thoroughly characterized and assessed as a key part of a mine’s management strategy. Proper management can create positive impact decades into the future.

As Duncan McDonald, Environmental Scientist at Ecometrix, says, “Mining is critically important to our economy, it’s our way of life, and part of that is responsibly managing its byproducts.”

For Ecometrix, helping clients understand and manage their materials can happen in different phases. We can either enter a new mining project to build materials management into its plan from the start or engage a mine that’s long been closed to investigate what happened many decades prior, and then assess what needs to happen today.

Whatever the case, working to understand mine materials management can be challenging and always evolving, but the right strategy, approach, expertise, and tools can create lasting impact.

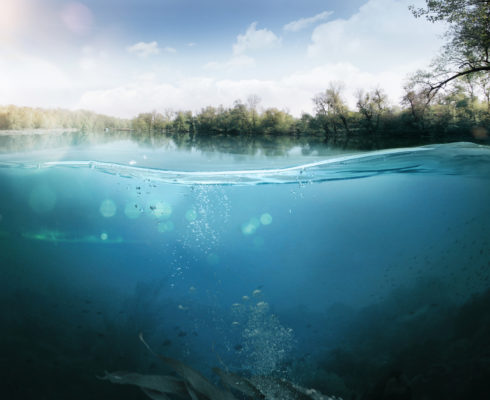

Duncan McDonald, Environmental Scientist, and Mike Bower, Environmental Scientist, collecting a water sample in the field.

Duncan McDonald, Environmental Scientist, and Mike Bower, Environmental Scientist, collecting a water sample in the field.

Changing perspectives

Like many sectors, the mining industry has undergone change in recent decades and there have been some key shifts in the thinking and approach to managing mine materials.

“One thing that has really improved, especially in Canada, is thinking about our legacy,” says Mike Bower, Environmental Scientist at Ecometrix. “We have to think about management strategies because we can’t just say ‘we’ll figure it out later.’ That culture has changed greatly in the last half century towards the importance of a good management strategy. Are we perfect? No. Have we got to where we need to be? No. But, compared to the 50s or 60s, it’s certainly come quite a long way.”

These changes are driven by regulations, a greater awareness from the public, and a sense of corporate ownership and responsibility in protecting the environment and Indigenous communities.

Language is another important part of this change, and both Duncan and Mike comment on favouring terms like “mine materials” instead of “mine waste”.

Gathering a tailings sample.

Gathering a tailings sample.

“The connotation of waste in people’s minds is a garbage heap or some glowing radioactive material,” Mike says. “We're taking rocks out of the ground and it’s a material that may have a risk to the environment, but it’s not a garbage heap.”

At Ecometrix, our experts make a point of not just keeping ahead of these perspectives but actively shaping science and pushing it forward with research.

“Something that Sarah [Barabash, Director of Mining Services at Ecometrix] said to me during my interview that made me want to join Ecometrix was that we’re all researchers at heart,” Duncan notes. “People on the mining team are constantly sharing papers and doing research to stay ahead of the curve as things evolve.”

Understanding the challenge

Every mine is different, and so are its challenges. As Duncan notes, “We deal with a lot of unique and novel ideas. To get the answers we’re looking for, we need unique and novel tests.”

It’s in this space that Ecometrix flourishes, harnessing its process of Environmental Intelligence™ and four principles of Thought, Application, Solution, and Communication (TASC) to deliver a result with lasting impact that’s truly tailored to the client.

Thanks to our in-house laboratory, we can make interpretations as testing progresses and make adjustments as required.

Thanks to our in-house laboratory, we can make interpretations as testing progresses and make adjustments as required.

In the case of mine materials management, that could be designing custom column tests to evaluate how new tailings and waste rock influence site water quality or column experiments to assess a potential co-disposal of mine contact water treatment residues with mine rock. It could be creating customized field cells and pan lysimeters to evaluate closure options where an organic material is planned to be introduced, enhancing reclamation efforts while determining any adverse influences on water quality.

Mike mentions a project in Ontario, where tests set up by Ecometrix a decade ago are still running today and collecting data. “We have this ability to customize and optimize these field programs to provide answers that might be required in regulations, like an environmental assessment, or if the client just wants to get ahead of understanding the potential risks.”

Tools in the box

This innovation is enhanced further by several resources Ecometrix has at its disposal. First, it has its own laboratory in Mississauga.

“Not a lot of consulting companies have their own labs,” Duncan says. “They work closely with external labs, as we do. With our own lab we can do it more efficiently, in-house, and make interpretations as testing progresses and make adjustments as required, where a technologist at an external lab can’t because they don’t know the intricacies of the program.”

Technology is also an important asset.

Core sampling in the field.

Core sampling in the field.

MineMod™ is a proprietary software that can help predict water quality and assist the decision-making process for mine managers by simulating the entire lifecycle of a mine. It was created as an extension of EMMA to forecast and provide input to various phases of the life of a mine such as feasibility studies, environmental assessments, construction, operation, closure, and rehabilitation.

For both Mike, who was involved in developing its concept, and Duncan, MineMod is an indispensable tool not just for its forecasting capabilities but for delivering them in a logical way that aligns everyone.

“Behind the scenes, what MineMod really does is give us water quality predictions, but it leads into a management strategy,” Mike says. “It gives us a lot more ways to show predictions versus actual measurements, which is a powerful tool we can use to get everyone involved in a project on the same page.”

A bright future

Looking ahead, Mike believes Canada has “a golden opportunity to lead the world in responsible resource development,” and both he and Duncan are excited to be part of it on the team at Ecometrix.

“I love the exposure to a wide variety of different projects,” says Duncan. “Something we get to do, which isn’t typical for consultants, is seeing a project all the way through. In a lot of larger firms, you come in and do one very niche, specialized component of a project and then pass it on to the next person. Here, we get to see things from start to finish.”

Using hydrodynamic modelling to support the mining sector

Explore the process we take to ensure pit lakes remain viable long into the future.